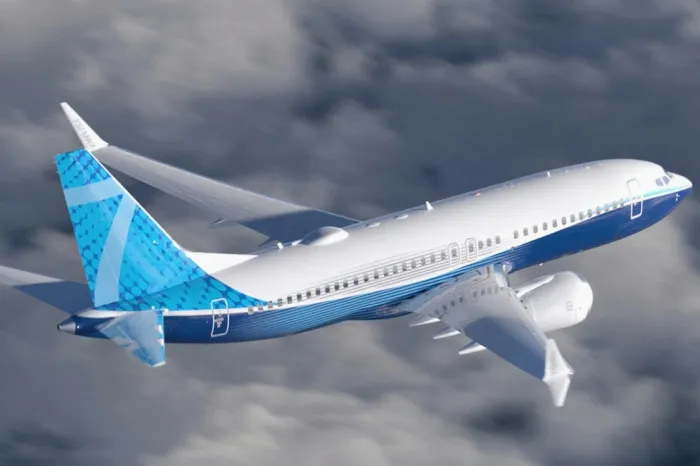

Boeing is grappling with mounting delays withinside the certification and manufacturing of its much-expected 737 Max 7 and Max 10 variants, because the U.S. Federal Aviation Administration (FAA) clarified that the duty for the present day holdups lies squarely with the plane manufacturer. The FAA careworn that, even though it is dedicating large assets to overseeing the process, the ball stays in Boeing’s courtroom docket in terms of resolving awesome technical problems and documentation had to steady popularity of the smallest and biggest variations of the Max family.

One of the important demanding situations going through Boeing is a snag withinside the engine de-icing machine. Engineers exposed that, below specific running conditions, extended use of the de-icing machine in dry air ought to reason the engine inlets to overheat. In intense scenarios, this can bring about structural harm to the cowling surrounding the engines, elevating protection worries that regulators can’t ignore. Addressing this trouble would require extra than revised pilot procedures—Boeing need to supply a sturdy technical restoration that meets the FAA’s rigorous protection standards.

The delays come at a time while stress from main airline clients consisting of United Airlines, Ryanair, Delta Air Lines, and Alaska Airlines has reached new heights. These carriers, every with sizable orders for the Max 10 variant, are relying on well timed deliveries to energy fleet renewals and aid formidable growth plans. Industry facts suggests Boeing is juggling corporation orders for extra than 1,425 devices of the Max 10, at the same time as the order backlog grows ever longer. With every passing month, airways are compelled to keep running older, much less fuel-green plane, stretching their potential plans and tightening the squeeze on their backside lines.

To confront those obstacles, Boeing is ramping up efforts at its Everett, Washington facility, in order to take care of very last meeting of the bigger Max 10 because of length constraints on the conventional Renton factory. The Everett plant, recognized for many years as the house of wide-frame icons just like the 747 and 777, is getting a facelift with the addition of a brand new 737 manufacturing line. The employer has additionally obtained regulatory approval to enhance the manufacturing fee from 38 to forty two plane in line with month, contingent on maintaining deliver chains sturdy and high-satisfactory manage measures in check. Recent activity postings for manufacturing managers and shift supervisors sign Boeing’s rationale to hit the floor jogging as soon as certification is in hand.

The ongoing drama has sparked debate over a way to streamline the plane certification method with out sacrificing safety. FAA administrator Bryan Bedford mentioned that reforms are underway to make regulatory opinions greater green and adaptive to new technology, however emphasised that last compliance—and the obligation for thorough engineering and documentation—rests with producers like Boeing. The final results of those efforts is being watched carefully throughout the enterprise, because the timing of recent Max version certifications should reshape competitiveness on key short- and medium-haul markets.

For Boeing, the stakes in 2026 couldn’t be higher. Certification of the 737 Max 7 and 10 will unencumber billions in sales and assist repair self belief amongst investors, industrial airlines, and the flying public. Until then, the aviation massive should hold to navigate technical setbacks, logistical headaches, and enterprise scrutiny—one thorough tick list and one manufacturing line at a time.